Downlight Springs | Manufacturing of Springs and Wireforms

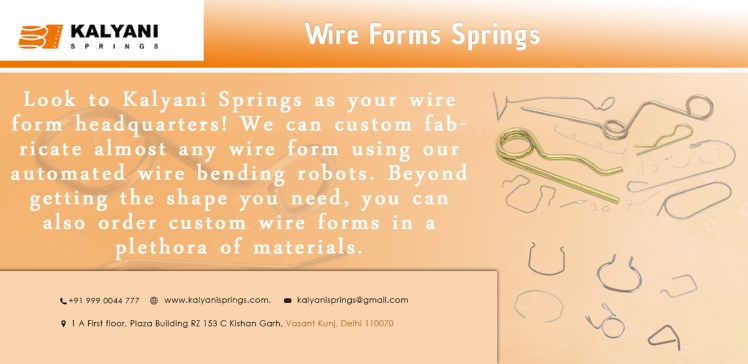

Kalyani Springs is manufactured and distributes company which manufactures a wide range if Downlight springs using the qualitative sourced from reliable vendors. We are an acclaimed firm in presenting a comprehensive array of LED Downlight Spring to the admired customers. These products are developed by our well-trained engineers who employing handpicked quality raw material keeping in mind the global quality norms and standards. Our engineers work on urbane machines and advanced technology to provide optimal gratifications. Furthermore to this, presented products are extremely sturdy and has even surface.

Integrated LED Downlights

I generally get asked by our customers that their electrician has suggested them that they must get LED downlights, so what can we recommend?

Firstly I would like to clarify some points, you can buy downlights that have the LED’s fitted inside them (integrated) or as I prefer a standard downlight that you then fit an LED into. Nowadays, when you go to the market for purchasing downlights most of the integrated LED downlights are sealed and the LED’s are not replaceable. Price does seriously dictate the quality of the fitting and often these downlights are sold in a term of ‘they will last forever!’ Sorry to say this but nothing lasts forever. Anything electronic has a chance of failure. The LED market is fast paced with new better models being released all the time.

We have several telephones calls a week into the office where people have had integrated LED downlights supplied and fitted by their electricians only to find a period of time late one or more has failed. They are then in a position that the model they have is no longer available and as the whole unit has to be replaced they cannot find one to match the rest in the ceiling. A customer just recently viewed a house on the market that was a very open plan with over 60 fittings, he saw that three were not working but assumed he could replace the lamps when he moved in. When he moved in he discovered they were integrated LED’s, the model was no longer available and after a lot of searching came to the realization that all the downlights would have to be changed. If he’d known this before he would have made it a condition of the sale that they were all replaced.

I will always recommend standard mains rated downlight with a GU10 LED lamp to be fitted inside. Then if the LED fails it is really easy to change the Lamp (bulb) and all issues are averted. The LED lamps that we sell by Eglo all have a five-year guarantee on them, so if you do have a failure then you can get a free of charge replacement. Some of the best-LED lamps on the market the manufacturers still expect a 2 to 3 percent failure rate!

Now I am discussing the best process for actually fitting the Downlight Springs:-

- Decide where you wish to place your chosen downlights measuring out the ceiling and marking the central point of the light. Now drill a small pilot hole through the ceiling.

- Now you have marked out the positions of the downlights it is a good idea to check the ceiling to ensure that there are no joists/ wires/pipes in the way. Where you drilled the pilot holes you can able to see a small pinprick of light coming through the ceiling. If you are unable to view the ceiling from above, it gets trickier. The best way is to determine which way the joists run and what the spacing between them are. You could then use an old wire coat hanger bent at a 900 angle to the width of the downlight. Insert the wire through the hole until the 900 bend is through. Now twist the wire a full 3600 and hopefully, it will not bump into any obstructions. Remember that it is good practice to make sure there is more room around where the downlight is to be fitted so that the downlight is not positioned too close to a joist or other obstacle. A 6-inch gap should be maintained around the downlight to guarantee the fitting does not overheat.

- In the instructions or on the box of the downlights it will say what the cut-out for that downlight will be. To get the best results, I will generally use a hole observed (a type of exercise bit) to the appropriate size of the downlight that can be purchased very inexpensively from most DIY stores. Alternatively, the use of a plasterboard saw (Pad Saw) can be used which eliminates the need for a drill and hole saw. For this method, you will need to draw a circle on the ceiling to the correct size as a guide for when you start to saw.

- Hopefully, now you have produced a clean cut hole in the ceiling, got the plaster out of your eyes and shaken yourself outside to stop you looking like Casper the ghost!

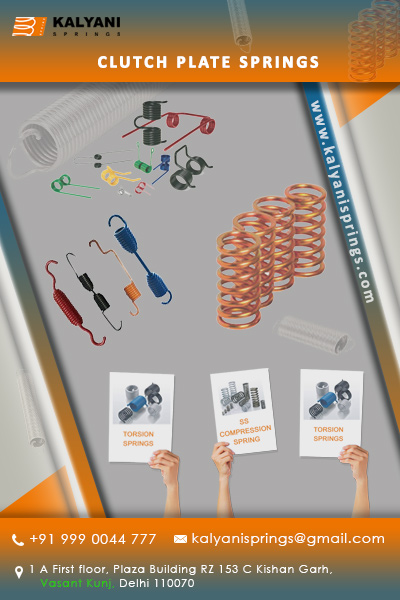

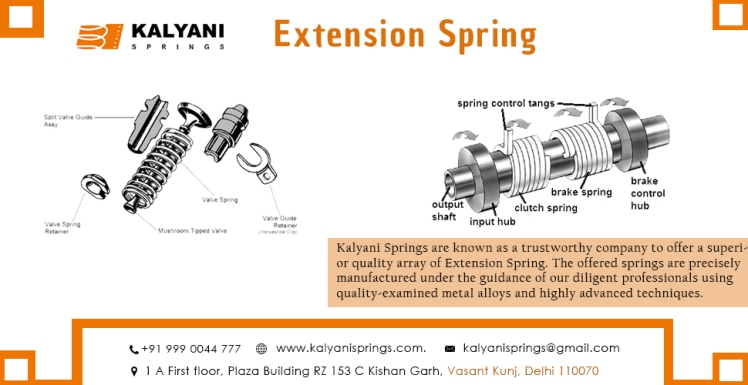

Once the wiring has been pulled through the hole the downlight can be wired. To complement the downlight into the hole properly, hold the two springs back against the sides of the downlighter and push-up into the hole. The suspension system springs then lie firm on the side the ceiling holding it in place. For more information regarding spring custom manufactured parts, please call us at 9990044777 or e-mail us at kalyanisprings@gmail.com or visit www.kalyanisprings.com.